What is Machine Vision?

Definition and Overview

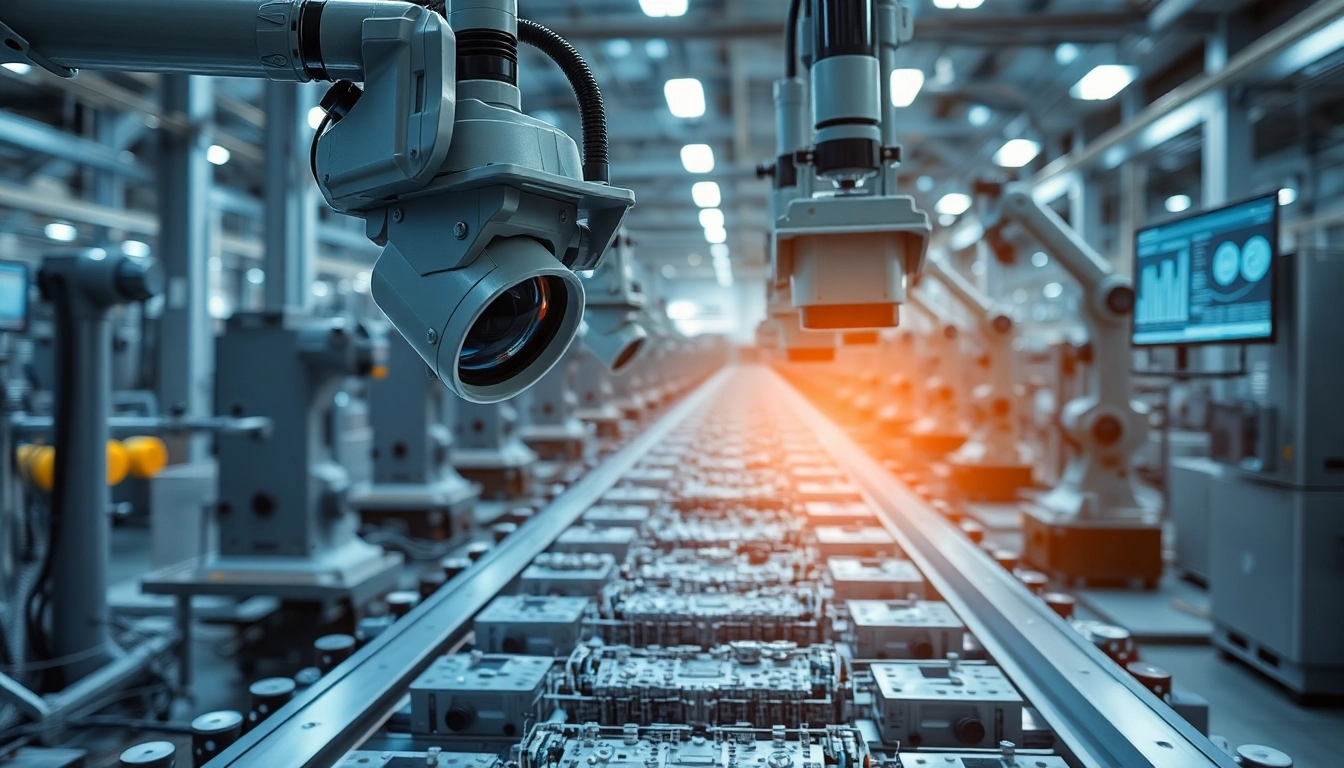

Machine vision refers to the technology and methods that enable machines to interpret visual information akin to human visual perception. Combining cameras, sensors, and advanced software, machine vision systems can capture, analyze, and respond to images in real time. These systems find applications across various industries, including manufacturing, logistics, and healthcare. The ability to perform tasks such as defect detection, identification, and inspection automatically enhances operational efficiency and accuracy. Today, many organizations are leveraging machine vision technology to streamline processes and improve quality control.

Historical Development

The roots of machine vision can be traced back to the early 1960s, when researchers began exploring the capability of computers to process visual information. Initially, the technology was constrained by the limited processing power of computers and the rudimentary imaging technology available. As digital cameras emerged in the late 1980s and early 1990s, significantly enhancing resolution and speed, machine vision systems began to proliferate in industrial applications. Over the years, advances in algorithms, artificial intelligence, and image processing techniques have transformed machine vision into a pivotal component of modern automation.

Key Components of Machine Vision Systems

Machine vision systems consist of several critical components that work in unison to facilitate image capture and analysis:

- Cameras: The eyes of machine vision systems, cameras capture visual data from the environment. Different types of cameras, such as CCD and CMOS, offer varying image quality and sensitivity.

- Lighting: Proper illumination is crucial for image clarity and contrast. Various lighting techniques, including diffuse, backlighting, and structured lighting, help enhance the features of the objects being inspected.

- Image Processing Software: This is the brain of the system, where algorithms analyze the visual data captured by the cameras to make decisions or trigger actions based on pre-defined criteria.

- Computers: The hardware that processes information and runs algorithms for image processing and analysis.

- Interface and Connectivity: To integrate with other systems, machine vision setups must include interfaces for data transfer and connectivity options, such as Ethernet, USB, or wireless communication.

Applications of Machine Vision

Quality Control in Manufacturing

One of the most significant applications of machine vision is in quality control and assurance within manufacturing. By automating the inspection process, companies can achieve higher accuracy, reduce manpower expenses, and enhance product consistency. Machine vision systems can detect defects, ensure proper assembly, and evaluate the dimensions of components quickly and reliably. For example, in the automotive industry, sensors can verify that parts are assembled correctly and meet specific tolerances before they proceed down the production line.

Automated Inspection Systems

Automated inspection systems are increasingly adopted across various sectors due to their ability to perform routine checks with precision and speed. These systems can inspect products ranging from printed circuit boards in electronics to packaging in food and beverage industries. Visual inspection allows for real-time feedback, which is critical for maintaining production flow. Integrating machine vision with robotics further enhances automation, enabling robots to make decisions on-the-fly based on visual data, such as reorienting components for accurate assembly.

Robotics and Machine Learning Integration

The advent of artificial intelligence and machine learning has significantly transformed how we approach machine vision. By incorporating AI algorithms, machine vision systems can learn from experience, improving their ability to identify patterns, classify objects, and even make predictive assessments based on historical data. For instance, in logistics, machine vision integrated with AI can identify and classify packages based on their dimensions, weights, and destination, leading to optimized sorting processes. This not only speeds up operations but also reduces errors significantly, enhancing overall efficiency.

Machine Vision Technologies

Cameras and Image Processing

Modern machine vision relies heavily on the advancements in camera technology. High-resolution imaging allows for the capture of detailed visual data, enabling precise analysis. The choice of camera—whether it’s a monochrome, color, or infrared—depends on the specific requirements of the application. Image processing techniques like filtering, edge detection, and pattern recognition help convert raw data into actionable information. Machine learning algorithms further empower these systems to identify and classify variations amongst images effectively.

Lighting Techniques

Lighting is a critical aspect of machine vision, as it greatly influences image quality. Various techniques are employed to optimize illumination according to the application’s needs. For instance, direct lighting can introduce shadows that obscure features, while diffuse lighting minimizes such issues. Backlighting techniques are frequently used when silhouettes are required, such as in the inspection of transparent materials. The implementation of structured lighting can further enhance image analysis by highlighting specific features or dimensions of objects.

Software Algorithms and AI

At the core of machine vision systems lies a suite of sophisticated software algorithms designed to interpret image data. These algorithms encompass various mathematical and statistical models, including convolutional neural networks (CNNs) and support-vector machines (SVMs), to facilitate deep learning and image recognition tasks. As machine learning evolves, algorithms can adapt by learning from new datasets, enhancing accuracy over time. This adaptability is crucial for applications that require continuous improvement or adapt to changing production requirements.

Benefits of Implementing Machine Vision

Increased Efficiency and Productivity

The automation of visual inspection processes leads to significant improvements in efficiency and productivity. Machine vision systems can work tirelessly without fatigue, enabling round-the-clock operations. They can process a high volume of products at unprecedented speeds, minimizing downtime in production lines. By catching defects earlier in the manufacturing process, businesses can significantly reduce the time and costs associated with rework and recalls.

Cost Savings and Waste Reduction

Implementing machine vision results in considerable cost savings over time. The initial investment in machine vision technology is often offset by the reduction in labor costs and increased efficiency. Furthermore, by improving quality control, companies can significantly reduce waste associated with defective products and unnecessary rework. The data generated from machine vision systems can also provide critical insights, enabling companies to refine their operations continually.

Enhancing Product Quality and Compliance

Quality assurance is paramount across all industries, and machine vision systems help ensure that products meet regulatory standards and quality benchmarks. By automating inspections and providing consistent quality checks, companies can oftentimes achieve higher standards of compliance. This is particularly vital in sectors such as food and pharmaceuticals, where product quality is inextricably linked to customer safety and regulatory adherence.

Future Trends in Machine Vision

Integration with Artificial Intelligence

As artificial intelligence evolves, its integration with machine vision systems is poised to redefine industry standards. AI can enable predictive maintenance and proactive quality control, helping organizations identify potential issues before they escalate. Machine vision systems augmented by AI can learn from past inspection data, allowing for more intelligent decision-making processes. This trend will lead to even greater levels of automation and efficiency across various sectors.

Emerging Technologies

Innovations in technology continue to play a significant role in shaping the future of machine vision. Developments in sensor technology, cloud computing, and edge computing are paving the way toward smarter and more interconnected systems. For instance, edge computing allows for real-time data processing closer to where it is generated, reducing latency and improving response times in high-speed environments. Additionally, the advent of 3D imaging and multispectral analysis introduces new capabilities to inspect more complex and diverse products.

Challenges and Considerations

While the benefits of machine vision technology are plentiful, organizations must also navigate several challenges. These may include high initial deployment costs, the need for ongoing maintenance, and the complexity of integrating new technologies with legacy systems. Companies should also consider the training and skill levels of the workforce to manage and maintain these advanced systems. A thoughtful implementation strategy that includes thorough training and gradual integration can help organizations mitigate these concerns and maximize their investment in machine vision.