Introduction to Stainless Steel Wire

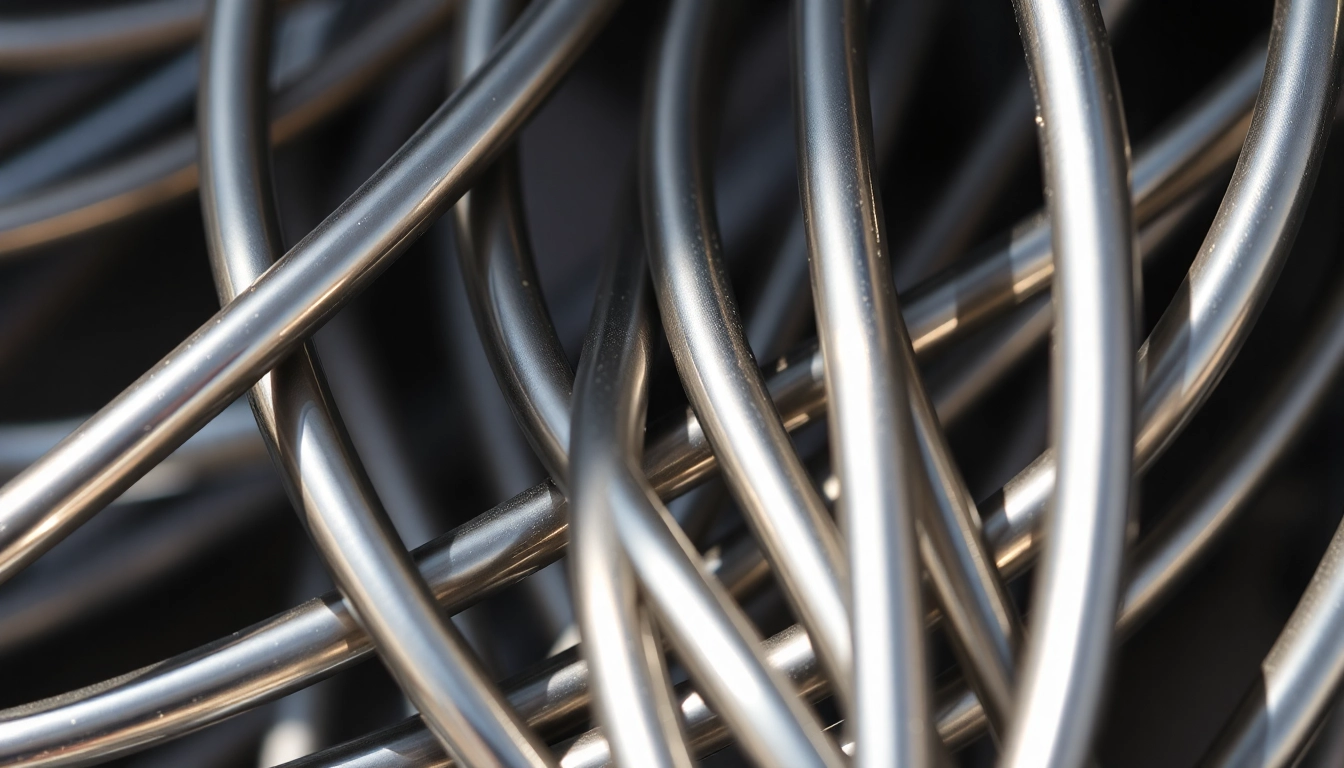

Stainless steel wire is an essential material in many industries due to its unique properties and versatility. It is primarily composed of iron, carbon, and a significant percentage of chromium, which provides corrosion resistance and durability. This makes stainless steel wire a favorable choice for various applications, including construction, manufacturing, and creative arts.

What is Stainless Steel Wire?

Stainless steel wire is a type of wire made from stainless steel—a metal alloy known for its excellent corrosion resistance and high strength. Available in various diameters, grades, and finishes, it can be used in countless applications, from simple crafts to complex industrial machinery. Its resistance to rust and staining sets it apart from other metal wires, making it highly favorable for long-term use in challenging environments.

Different Grades of Stainless Steel Wire

Several grades of stainless steel wire are available, each tailored for specific applications. The most commonly used grades include:

- 304 Stainless Steel: Known for its good corrosion resistance and weldability, making it a popular choice for general applications.

- 316 Stainless Steel: Offers superior corrosion resistance compared to 304, especially in chloride environments. It is ideal for marine applications.

- 430 Stainless Steel: Primarily used for decorative applications due to its lower corrosion resistance. It is magnetic and better suited for dry environments.

Importance of Wire Composition

The composition of stainless steel wire is critical in determining its properties and applications. The inclusion of chromium is vital for corrosion resistance; the more chromium in the alloy, the better its resistance to rust and corrosion. Nickel is another significant element that enhances ductility and formability, which is essential for wires used in delicate and intricate applications like jewelry making.

Applications of Stainless Steel Wire

Industrial Uses of Stainless Steel Wire

Stainless steel wire is extensively used in various industries due to its strength and corrosion resistance. It finds applications in the following areas:

- Manufacturing: It is widely utilized in the production of springs, wire rope, and other components requiring strength and durability.

- Automotive: Stainless steel wire is used for making components that resist rust and wear, including exhaust systems and springs.

- Aerospace: Due to its high strength-to-weight ratio and resistance to extreme temperatures, it is found in many aircraft components.

- Medical: Stainless steel wires are crucial in surgical instruments and devices due to their non-reactivity and sterility.

Stainless Steel Wire in Jewelry Making

In recent years, stainless steel wire has gained popularity among jewelry makers for several reasons:

- Durability: Stainless steel jewelry withstands everyday wear, making it a smart choice for items that need longevity.

- Hypoallergenic Properties: Many stainless steel wires contain minimal nickel, reducing the risk of allergic reactions.

- Versatile Aesthetics: Available in various finishes, stainless steel wire can achieve a sleek and modern look, appealing to diverse customer preferences.

Construction and Engineering Applications

In construction, stainless steel wire is commonly used in:

- Reinforcement: It is often embedded in concrete or used in steel mesh for added strength.

- Architectural Features: Decorative elements, cables, and supports are made with stainless steel wire, combining function with aesthetics.

- Safety and Security: Stainless steel wire rope is frequently utilized for safety harnesses, fencing, and protective barriers due to its high tensile strength.

Advantages of Using Stainless Steel Wire

Corrosion Resistance and Durability

One of the most significant advantages of stainless steel wire is its excellent corrosion resistance. The chromium content creates a passive layer that protects the metal from environmental factors that typically cause corrosion in other metals. This makes it an ideal material for outdoor applications and areas with high humidity or exposure to harsh chemicals.

Tensile Strength and Versatility

Stainless steel wire possesses exceptional tensile strength, which allows it to withstand heavy loads without breaking. This characteristic, combined with its malleability, enables it to be shaped into various forms, making it versatile for multiple applications, from industrial machinery to intricate jewelry pieces.

Cost-Effectiveness in Various Applications

While the initial cost of stainless steel wire may be higher than other types of wire, its durability and low maintenance requirements typically lead to lower overall costs in the long run. Its resistance to wear and environmental damage means fewer replacements and repairs, making it a cost-effective option for manufacturers and builders.

Choosing the Right Stainless Steel Wire

Factors to Consider When Selecting Wire

When choosing stainless steel wire for a specific application, consider the following factors:

- Wire Type: Determine if a solid wire, braided wire, or specialty wire is needed based on the application.

- Grade: Select the appropriate grade of stainless steel based on the environmental conditions and required strength.

- Diameter: The thickness of the wire plays a critical role in its performance. Ensure that the diameter suits the load and application demands.

Comparing Stainless Steel Wire Types

Different types of stainless steel wire serve various purposes. For example, 304 and 316 types are known for their general-purpose use. However, 316 is preferable for marine applications due to its superior corrosion resistance. Consider specific project needs, such as exposure to saltwater or high temperatures, when making a comparison.

Guidelines for Optimal Performance

To ensure optimal performance when using stainless steel wire, follow these guidelines:

- Conduct a thorough assessment of environmental conditions to choose the right wire grade.

- Utilize the appropriate techniques for cutting, bending, and forming to prevent damage.

- Implement proper storage methods to avoid contamination and maintain the wire’s integrity.

Maintenance and Longevity of Stainless Steel Wire

Cleaning Stainless Steel Wire

Regular cleaning is essential to maintain the appearance and performance of stainless steel wire. To clean, use a mild detergent and a soft cloth or sponge, avoiding abrasive materials that may scratch the surface. For heavily tarnished wire, specialized stainless steel cleaners can restore its shine.

Preventing Rust and Damage

While stainless steel wire is resistant to rust, it is not entirely immune. Prolonged exposure to moisture, especially in combination with contaminants like salt or chemicals, can lead to oxidation. To prevent rust, ensure the wire is dry and clean after use, and consider applying a protective coating for added durability in harsh environments.

Enhancing the Lifespan of Stainless Steel Wire

To enhance the lifespan of stainless steel wire, perform routine inspections to detect signs of wear or corrosion early. Store excess wire in a dry, climate-controlled environment, and abide by proper installation techniques to ensure it performs optimally throughout its lifespan.